Subtotal: $318.00

- +92 21 ---------

- Elevatia Learning Hub, Port Qasim, Karachi

- info@elevatialearninghub.com

Air Compressors Maintenance & Troubleshooting

Air Compressors Maintenance & Troubleshooting

Air Compressors Maintenance & Troubleshooting

Introduction:

Compressed air plays a critical role in the daily operations of numerous industrial settings and manufacturing plants. It is indispensable for performing some of the most vital tasks in industries such as Fertilizer, Power, Oil & Gas, Petrochemical, Automobile, Food, and Aviation. Air compressors have become an essential component in these sectors, underscoring their significance in modern industrial processes.

Objective:

- This course is designed to provide an insight into the Fundamentals; Classification and Application of Air Compressor. The program also focuses on key aspects such as selection criteria; inspection; and maintenance regimes for air compressors in various facilities. Troubleshooting of air compressors is a very critical aspect of this training course. Participants will be imparted with practical knowledge of Air Compressor Day-to-day & critical problems / failure and troubleshooting.

Who Should Attend:

- Mechanical Engineers

- Mechanical Technicians & Supervisor

Contents:

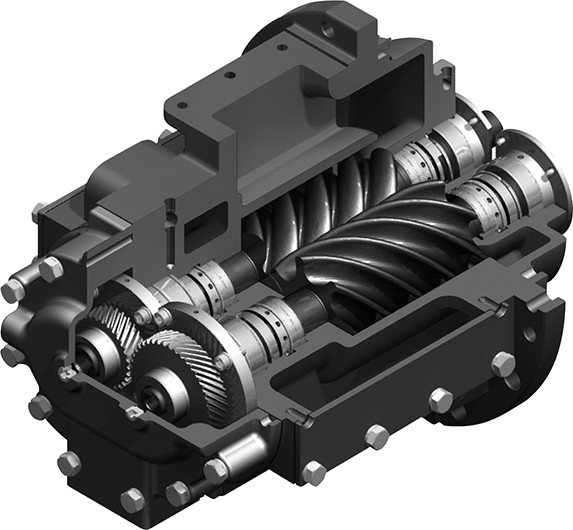

- Introduction & Fundamentals of Compressors

- Types; Application & Selection Criteria of Air Compressors

- Concept / Application of Dry & Oil flooded Air Compressors

- Inspection & Maintenance Regimes of Air Compressors

- Troubleshooting of Air Compressors

- Case Study Related To Problems / Failures Related To Air Compressors

| Course ID | Course Title | Start Date | End Date |

|---|

-

Years of Experience:

20 Years

-

Area of Expertise:

Rotating Equipment Maintenance, Static Equipment Maintenance, Maintenance Planning, Project Management.

-

Achievements:

Mechanical Engineer with diversified experience of 20+ years in the fertilizer and power sector, leading teams for plant maintenance, BMR and construction projects, commissioning, and start-ups. Result oriented individual with a track record of delivering simultaneous projects on time. It includes engineering reviews, reliability improvement, Planning & execution of Outages, Parts Repairs, Material Inventory management, Maintenance and Troubleshooting of rotating equipment i.e. Gas Turbines, Steam Turbines, Generators, Centrifugal Compressors, Gear boxes, Pumps, Coal Volumetric Feeders, Bed Ash Coolers, Coal Crushers & Coal Vibrating Screens.

HTML5 Course

HTML5 Course JS ES6 Course

JS ES6 Course PHP Course

PHP Course Python Course

Python Course WordPress Course

WordPress Course